Top 10 Best Laser Engraver & Cutting Machine 2023 For Beginners With Ultimate Guide

Best Laser Engraver 2023: Are you searching for one of the best laser engraver machines to take your at-home enterprise to a different degree? We might have one thing precious in the retailer for you!

Whether or not you’re a DIY fanatic, an aspiring home-based enterprise proprietor, or perhaps a beginner within the tech area, it’s essential to have heard of laser engravers.

Laser reduction and engraving are rising as well-liked nowadays. It’s not solely demanded by product designers and small enterprise house owners to earn from their talent; however, even hobbyists to brighten their properties with their artwork.

With the rise in the reputation of laser engraver and cutter instruments, you may have many choices. Selecting one of the best laser engraving tools might be hectic, particularly for those who need help knowing and don’t know where to start.

However, fear no extra, as, in this article, we have now offered complete information on one of the best ten laser engravers for first-year students in 2023. Let’s get begun!

10 Best Laser Engravers Price

Top 10 Best Laser Engravers For Beginners in 2023

I lately had the expertise to purchase a laser engraver for a buddy. My takeaway from the entire looking-out course is that navigating all potential choices for one of the best laser engravers is extraordinarily tough.

Also Read

To simplify the method, I’ve narrowed down the various choices based primarily on my analysis. Whether or not you desire a budget-friendly laser engraving instrument or are searching for one which meets your particular necessities for the fabric or utilization, this record of one of the best ten laser engravers for first-year students in 2022 has one thing for everybody.

What are Laser Engravers?

A laser engraver is a tool used to engrave everlasting marks on surfaces. It etches something from wood, stone, marble, tile, cardboard, aluminum, and even glass to create distinctive designs.

Laser engravers work by exposing a slim laser to the fabric. The extreme warmth of the laser causes the fabric to soften, burn and vaporize, leading to an everlasting abrasion-resistant engraving.

Furthermore, the excessive precision of laser engraving tools permits designing of intricate particulars on supplies without utilizing several instruments. Firms use laser engravers to etch serial numbers and logos of their merchandise. However, it would be best if you used it to carve your identity or surroundings on wooden or metallic.

10 Best Laser Engravers

- xTool D1 Pro

- Atomstack X30 Pro

- Atezr V35 Plus

- Sculpfun S30 Pro Max

- ORTUR Laser Master 3

- Atezr P20 Plus

- Atomstack S20 Pro

- Atomstack X20 Pro

- Atomstack A20 Pro

- Longer Ray5 20W

Now we are describing one by one which is the Best Laser Engraver 2023.

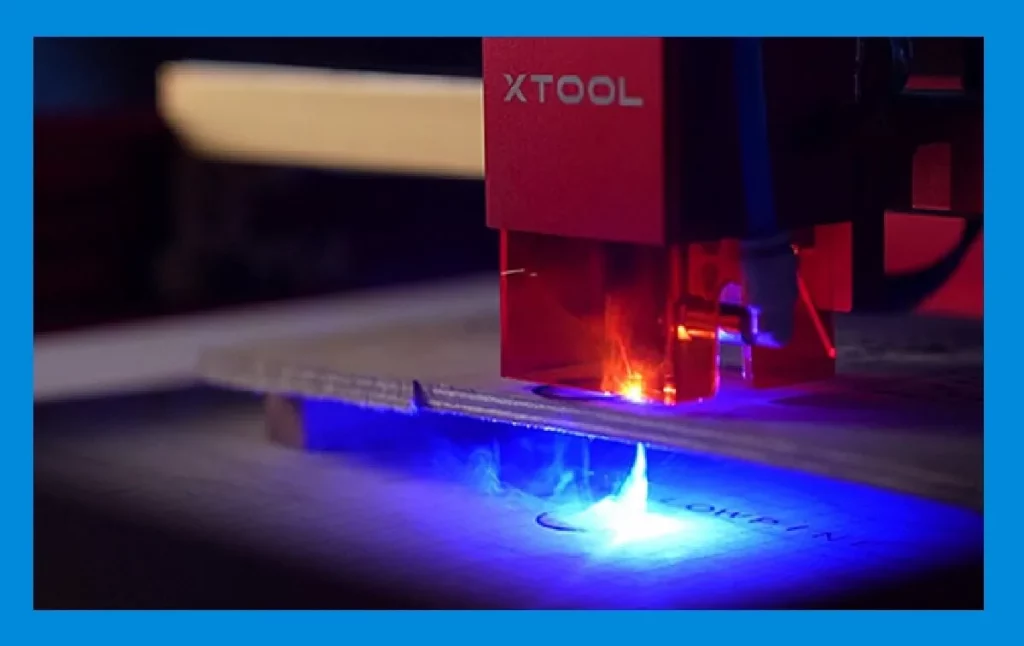

1. xTool D1 Pro

The xTool D1 Pro 20W laser cutter and engraver has the world’s most robust 20W diode laser. It cuts 12mm of wooden or 8mm of black acrylic in ONE PASS. This means you can rapidly hammer out more significant tasks.

The XTool D1 Pro is a laser engraving machine within the higher value vary. But for a matter of just below $699.99, you also get a lot rather than provide.

xTool D1 Pro Price

- Feature 1: 10mm Basswood Cuts

- Feature 2: 20W Laser Power

- Feature 3: Up to 400mm/s Working

- Feature 4: Dual Beam Design

- Feature 5: Large Engraving Range

- Feature 6: Synchronous Belt

Features

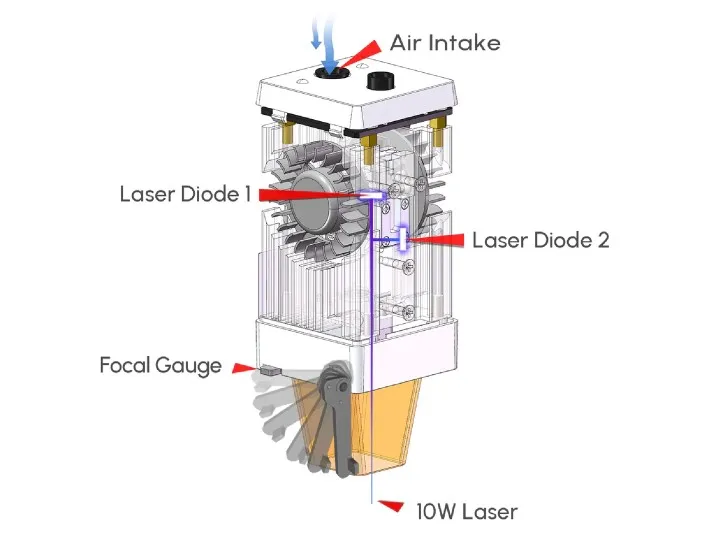

The 430 x 390 mm laser engraver is provided with a 20-watt laser diode that cuts wooden as much as 10 mm and acrylic as much as eight mm thick. To obtain the 20-watt energy, the XTool D1 Pro bundles a complete of 4 5-watt lasers.

The positive 0.08 x 0.10 mm laser level shouldn’t be solely appropriate for chopping but additionally for engraving. A strong aluminum body offers the laser engraver its stability. The linearly guided laser strikes over the engraving floor at as much as 400 mm/s.

The result’s an exact engraving with an excessive stage of element. The focus could be adjusted within the 50 mm vary. The laser peak is adjusted by way of a quick-release fastener.

Specification

| General | Item Name: xTool D1 Pro Brand: xTool Model: D1 Pro Type: Laser Engravers Status: Available |

| Features | High Accuracy Cutting & Engraving 0.08mm*0.06mm ultra-fine compression spot Industrial Grade ALL-STEEL Wheel & Shaft Made of aluminum alloy and steel Super powerful laser beam oxidizes Adjust focus in 3 seconds Equipped with flame sensor Tension Wheel & Synchronous Belt |

| Specifications | Machine Power: 90W Laser Module Output Power: 20W Laser Spot: 0.08 mm Wavelength: 450 – 460 mm Routing Speed: 160 mm/s Working Area: 432*406 mm Max. Workpiece Height: 50 mm Voltage Input: 100-240V 50-60HZ Voltage Output: 12V 7A 84W Connecting Interfaces: Wi-Fi, USB, Offline Use Certification: FCC, FDA Operating Systems: Windows, macOS, Android, iOS Control Software: Laserbox Software, Laserbox App |

| Dimensions & Weight | One Package Weight: 8.50kgs / 18.75lb Carton Weight: 22.00kgs / 48.50lb Carton Size: 84cm * 42cm * 32cm / 33.07inch * 16.54inch * 12.6inch Loading Container: 20GP: 236 cartons * 2 pcs = 472 pcs 40HQ: 548 cartons * 2 pcs = 1096 pcs |

| Package Contents | 1 x xTool D1 Pro 10W Machine 8 x Raisers 1 x RA1 Rotary Roller |

2. Atomstack X30 Pro

Atomstack has always led the business within the discipline of diode laser engravers. Atomstack X30 Pro Laser Engraving & Cutting Machine with 160W 6-Core. Last October, Atomstack debuted X7 Pro, the primary dual-core 10W Laser Engraving Machine, and it is now the best-selling 10W system.

After various analyses and improvements by their engineers, a couple of months later, they launched the 20W quad-core laser, used within the star mannequin Atomstack X20 Pro and has sturdy slicing energy. This time, don’t be too shocked.

Atomstack X30 Pro Price

- Feature 1: World’s First 6-core Diode Laser

- Feature 2: World’s First 33W Laser power

- Feature 3: 20mm wood Cutting in One-PASS

- Feature 4: Built-in Powerful air Assist kit

- Feature 5: Sturdy and easy to install

- Feature 6: New laser with knob

Features

Atomstack said they would launch the world’s first six-core 30~36W laser engraver, the Atomstack X30 Pro. As we all know, the “X” sequence is the high-end sequence of Atomstack, essentially representing the most superior laser expertise.

The mixture of 6 laser beams with 6W energy right into a single ultra-powerful laser beam can theoretically be 36W. However, there will undoubtedly be some power loss, so 33W laser output is already very environmentally friendly. You may also like others brand Sculpfun S30 Pro Max and ORTUR Laser Master 3.

Specification

| General | Item Name: Atomstack X30 Pro Brand: Atomstack Model: X30 Pro Type: Laser Engravers Status: Available |

| Features | Ultra-high Power High efficiency Equipped with F30 Pro upgraded air-assist kit Atomstack self-research 32-bit motherboard New upgrade of laser module Atomstack APP Panoramic filtered glass eye protection Sturdy and easy to install Upgraded version of high-performance Precision scale line axis Upgraded compressed spot coupling technology New laser with knob |

| Specifications | Machine Power: 160W Electric Power: 120W Laser Power: 33-36W Laser Wavelength: 455±5nm Engraving Precision: 0.01mm Working Area: 410*400mm Focusing Method: Fixed focus laser, no focusing Operating Software: LaserGRBL, LightBurn Operating System: Win XP / Win 7 / Win 8 / XP / Win 10 / Win 11 / Mac File Format: NC, BMP, JPG, PNG, DXF Data Transmission: USB connection, TF card Power Input: 100-240V AC, 50/60HZ Power Output: 24V 5A Certification: CE FCC RoHS FDA PSE |

| Package Contents | 1* Installation screws 1* Kit 4* Foot pad foam 1* Focusing sheet 3* Acrylic sheet 3* Wooden sheet 10* Wire ties 1* Desiccant 1* Brush 1* Dustless cloth 1* Card reader 1* TF card 1* Power adapter 1* Manual 1* Data cable 1* Touch screen assembly 1* HDMI cable 1* Laser module 1* X-axis assembly 1* Y-axis left profile 1* Y-axis right profile 1* Base upper profile 1* Bottom profile 3* Foot bracket |

3. Atezr V35 Plus

This Christmas season, Atezr, the innovation-driven international tech model, proclaims the launch of the Atezr V35 Plus laser engraving and chopping machine, a robust SIX-beam diode laser engraver with 35W optical energy at present.

The engraving and chopping space of the Atezr V35 Plus can attain as much as 430 × 430 mm, greater than 100 different supplies will be lower, and the working pace is upgraded to 24800 mm/min. It makes folks’ artwork come to life at a decision of as much as 423 DPI.

Atezr V35 Plus Price

- Feature 1: 35W Powerful laser

- Feature 2: 430*430 mm Workspace

- Feature 3: 0.06*0.1mm compressed spot

- Feature 4: Fine engraving and strong cutting

- Feature 5: Touch screen offline operation

- Feature 6: 12mm black acrylic board

Features

The high-precision laser spot is improved to 0.06 × 0.1 mm, reaching a decision of 423 DPI and aiding artists and engraving aficionados in producing real works or batch artwork processing. The Atezr V35 Plus can be a dependable possibility for industrial-strength mass manufacturing for small- and medium-sized organizations.

The Atezr V35 Plus is a robust diode laser engraver and cutter, constructed by the Atezr group after years of analysis on laser engraving machines, which might meet the wants of the enormous, medium, and small engraving and chopping tasks.

Specification

| General | Item Name: Atezr V35 PLUS Brand: Atezr Model: V35 PLUS Type: Laser Engravers Status: Available |

| Features | Ultra fine laser engraving and cutting Focus lever in less than a minute Automatic detection of limit switch limits Color engraving on stainless steel |

| Specifications | Engraving Size: 430mm*430mm Machine Power: 160W Laser Power: 35W Spot Size: 0.06mm*0.1mm Engraving Accuracy: 0.01mm Laser Focal Length: 40mm Laser Wave: 455±5nm Focusing method: Fixed focus lever without focusing Operating Systems: Windows/macOS/Android/iOS Control Software: LaserGRBL/LightBurn Connecting Interfaces: USB/Wi-Fi/TF Card Motherboard: 32-Bit Control Board With Wifi Offline Display Screen: 3.5-Inch Color Touch Screen |

| Dimensions & Weight | Machine Net Weight: 8.78kg Packing Weight: 17.7kg Equipment Size: 644mm*680mm*168mm Packing Size: 743mm*503mm*155mm |

| Package Contents | 1 x Y-axis left and 1 x right slide rails 1 x Optical axis 1 x Foot bracket 4 1 x HDMI cable 1 x USB card 1 x Air assist 1 x Atezr P20 Plus 1 x Upper and 1 x lower support beam 1 x Rubber Tube 1 x Wood chips 3PC 1 x Metalmat board 1 x Safety goggles 1 x Display screen 1 x Wire 1 x Laser module 1 x SE OP 1 x Mounting screws 1 x X – axis rail 1 x Product manual 1 x Dust – free cloth 1 x eet 3PCS 1 x Power cable 1 x Power adapter 1 x Toolkit 1 x Brush |

4. Sculpfun S30 Pro Max

The best SCULPFUN S30 Pro Max 20W Laser Cutter To be exact, that is the fourth model to launch a 20W diode laser engraver. Let’s undergo the timeline: the primary is the Atomstack X20 Pro, the second is xTool D1 Pro, the third is the Atezr P20 Plus, and the fourth is the SCULPFUN S30 Pro Max. We’ve already coated the primary three, so now I’ll give attention to the brand new 20W Laser.

Sculpfun S30 Pro Max Price

- Feature 1: Automatically Controlled Air Assist

- Feature 2: High-Pressure Air Assist Nozzle

- Feature 3: Ultra-thin 20W Laser

- Feature 4: Replaceable Protective Lens

- Feature 5: Expandable Engraving Area

- Feature 6: Right-angle Measuring Ruler

Features

Now we see an analogous air help system on the SCULPFUN S30 Pro Max, which permits the engraver to blow away smoke and dirt whereas engraving or chopping, reducing the floor temperature of the fabric and getting lovely work.

The temperature is just too excessive to make the lens break. But don’t worry, SCULPFUN within the new bundle, geared up with a replaceable lens, remedy the buyer’s worries.

It is price mentioning that this time SCULPFUN geared up two variations of extension equipment for their S30 collection. The unique engraving space is about 400*400mm.

Specification

| General | Item Name: Sculpfun S30 Pro Max Brand: Sculpfun Model: S30 Pro Max Color: Blue Type: Laser Engravers Status: Available |

| Features | High-Pressure Air Assist Nozzle Ultra-thin 20W Laser Replaceable Protective Lens Expandable Engraving Area Right-angle Measuring Ruler Safety Design Sturdy and Durable Aluminum Alloy Frame Industrial-grade Cutting Accuracy Upgraded 32-bit Air-assist Motherboard |

| Specifications | Diode Laser Output Power: 20W (note: that this is light energy, not electrical energy) Laser Focus: 0.08×0.1mm Laser Wavelength: 455±5nm Focusing Method: fixed focus column + sliding device Laser Protection Cover: Equipped with a detachable laser protection cover to protect the eyes. You can adjust it up and down, or remove the goggles Machine Information: Engraving Accuracy: 0.005mm Engraving Area Size: the standard version is 410*400mm, which can be expanded to 935x400mm or 935x905mm Machine Power: about 60W Air Pump: Type: mainboard-controlled air pump Voltage: 12V Flow: 30L/min Air Hose Inner Diameter: 7.5mm Operating Software: LightBurn (with air assist function M8), LaserGRBL, LightBurn, Benbox, GrblController, LiteFire, support Windows system, support MAC system Supported File Formats: NC, BMP, JPG, PNG, DXF, and other image formats Data Transmission Method: USB connection or Bluetooth wireless connection Power Input: 100-240V AC, 50/60HZ Power Output: 24V 5A |

| Dimensions & Weight | Product Weight: 7kg Package Weight: 15kg Product Size(L x W x H): 230*235*625mm Package Size(L x W x H): 260*500*650mm |

| Package Contents | 1 x S30 Pro Max Laser Engraver 1 x Laser Repair Kit 1 x 12V Automatic Air Pump 3 x A4 Size 3mm Wooden Board 2 x Limit Switch 1 x 12V 5A Power Adapter 1 x Power Cord 1 x USB Cable 1 x Air Tube 1 x Installation Tool Kit 1 x Laser Goggles 1 x A4 Metal Backing Plate Step 1-6 Install the Package 1 x X-axis Assembly 2 x X Profiles 2 x Y Profiles 1 x Control Box Assembly 3 x Support Feet 1 x User Manual |

5. ORTUR Laser Master 3

ORTUR Laser Master 3 10W Laser Engraving Machine, as soon as a number one model within the diode laser engraving sector, has declined for the previous two years. We have observed that two different Chinese manufacturers, Atomstack and xTool, have emerged and are already forward of Ortur by way of expertise.

This is demonstrated by the truth that the opposite two manufacturers have launched the Atomstack X7 Pro and xTool D1 with 10W laser energy, whereas Ortur continues to be within the 5W vary. The most outstanding small industrial excessive energy laser engraver and cutter for everybody.

ORTUR Laser Master 3 Price

- Feature 1: Super High Power Laser

- Feature 2: 10W Upgraded Laser Module

- Feature 3: Laser Cutter with Wide

- Feature 4: Totally User Friendly

- Feature 5: 7 Safety Features

- Feature 6: Depth of 8mm field

Features

Therefore, in 2022, the purpose may be to consider that Ortur will tackle the problem of Atomstack and xTool with its subsequent mannequin, the Laser Master 3, outfitted with a 10W dual-core laser module.

When Ortur Laser Master 3 involves laser engraving machines, it’s unattainable to not point out the engravers of the Ortur model, which is a pacesetter in this sector. Ortur is not an unknown firm as a producer of laser CNC tools.

As we all know, the 10W laser module comprises two 5W laser beams coupled collectively and can reduce woodenly and engraving metallic. For instance, it will possibly lower 20mm softwood boards, which can’t be completed with a 5W laser.

Specification

| General | Item Name: Ortur Laser Master 3 Brand: Ortur Model: Laser Master 3 Type: Laser Engravers Status: Available |

| Features | Better expertise Faster engraving, as much as 20,000mm/min Stronger reducing energy,10w True Optical Power Higher precision, TMC silent Stepper drivers Smarter Operation Easy to make use of; Engrave what you need in time Safety efficiency enhancement Seven main safety ensures Better adaptability More utilization situations Abundant accent ecology |

| Specifications | Machine Size: 580 x 550 x 150mm Engraving Area: X400 X y400mm Engraving Speed: 0-20000mm/min Spot Size: About 0.05×0.1 mm Laser Wavelength: 455+5nm Focus: 50mm (From radiators to objects) Modulation Mode: TTL |

| Dimensions & Weight | Net Weight: 4.3KGS / 9.48lb Gross Weight: 6.5KG/14.33lb Package Size: 660x240x200mm / 26″ x9.5″ x 7.9″ |

| Package Contents | 1 x Laser Master 3 Engraver Kit |

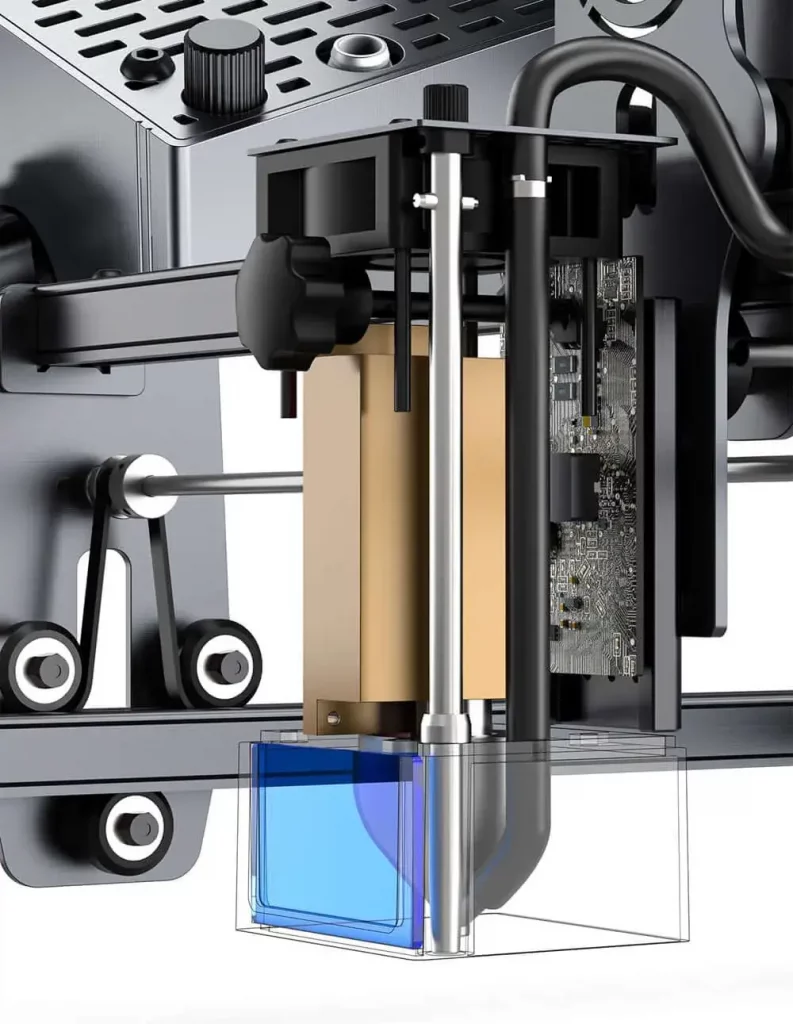

6. Atezr P20 Plus

Atezr P20 Plus 20W Laser Engraving Machine is the third 20W diode blue laser engraver available on the market right now, and ATEZR is again with their first mannequin, the P20 PLUS. The first is the X20 Pro from Atomstack, and the second is the D1 Pro from xTool, each of which shares the general characteristic of getting four diode lasers coupled into one 20W massive laser beam.

Atezr P20 Plus Price

- Feature 1: Powerful diode laser engraver

- Feature 2: Working area to 430mm*430mm

- Feature 3: 15mm solid wood cut in one-pass

- Feature 4: 12mm dark acrylic

- Feature 5: 0.3mm thin sheet metal cuts easily

- Feature 6: 20W Highest Dual Laser

Features

ATEZR brings three laser heads with 5W, 10W, and 20W output energy, corresponding to a few fashions: P5, P10, and P20 Plus. The frames of those fashions are identical. However, the working space is barely completely different, so I’ll now deal with the P20 Plus.

Do you want a bigger working space? The Atezr P20 Plus has an engraving space of 430*430mm for giant format work. The modular design permits clients to arrange the machine efficiently in lower than 20 minutes. The software program you can obtain are Lightburn and LaserGRBL, the previous is paid software program, and the latter is free.

Specification

| General | Item Name: Atezr P20 Plus Brand: Atezr Model: P20 Plus Type: Laser Engravers Status: Available |

| Features | Ultra fine laser engraving and cutting Focus lever in less than a minute Automatic detection of limit switch limits Color engraving on stainless steel |

| Specifications | Engraving Size: 430mm*430mm Machine Power: 120W Laser Electric Power: 90W Laser Module Output Power: 20-24W Spot Size: 0.08mm*0.06mm Engraving Accuracy: 0.01mm Laser Focal Length: 40mm Laser Wave: 455±5nm Focusing method: Fixed focus lever without focusing Operating Systems: Windows/macOS/Android/iOS Control Software: LaserGRBL/LightBurn File Type(s): SVG/DXF/JPG/JPEG/PNG/BMP/TIF/CR2, etc. Connecting Interfaces: USB/Wi-Fi/TF Card Motherboard: 32-Bit Control Board With Wifi Offline Display Screen : 3.5-Inch Color Touch Screen |

| Dimensions & Weight | Machine Net Weight: 8.78kg Packing Weight: 11.28kg Equipment Size: 644mm*680mm*168mm Packing Size: 585mm*585mm*285mm |

| Package Contents | 1 x Y-axis left and 1 x right slide rails 1 x Optical axis 1 x Foot bracket 4 1 x HDMI cable 1 x USB card 1 x Air assist 1 x Atezr P20 Plus 1 x Upper and 1 x lower support beam 1 x Rubber Tube 1 x Wood chips 3PC 1 x Metalmat board 1 x Safety goggles 1 x Display screen 1 x Wire 1 x Laser module 1 x SE OP 1 x Mounting screws 1 x X – axis rail 1 x Product manual 1 x Dust – free cloth 1 x eet 3PCS 1 x Power cable 1 x Power adapter 1 x Toolkit 1 x Brush |

7. Atomstack S20 Pro

Are you thinking to buy a Laser Engraver Cutter? we are introducing a best Laser Engraver Cutter 2022 that is ATOMSTACK S20 Pro 130W Laser Engraving Cutting Machine with Air Assist Kits for you. ATOMSTACK are provided Quad-core Diode Laser, 0.08 x 0.1mm Compressed Spot, Offline Engraving, 400x400mm.

ATOMSTACK S20 Pro is the primary 130W semiconductor laser engraving machine, which uses the latest four 6W laser coupling expertise technology to provide the output energy soars to 20W, and the tight spot is lowered to 0.08mmx0.1mm dimension.

Atomstack S20 Pro Price

- Feature 1: 4 Compressed Spot Technology

- Feature 2: Strong Cutting & Engraving Capability

- Feature 3: More Intelligent Engraving

- Feature 4: Built-in Air Assist Kit

- Feature 5: Smart Limit Switch Design

- Feature 6: Panoramic Filter Coated Glass

Features

According to the image’s 256 utterly different grayscale data, the laser vitality is mechanically adjusted to attain the complete mission’s subtler distinction in addition to an extra pure transition between colors. ATOMSTACK S20 Pro 20W laser engraver can minimize 15mm thick tung wooden board and 8mm, thick black acrylic board at one cross and minimize greater than 40 sorts of supplies corresponding to 0.05mm thick chrome steel board.

You can join the S20 pro laser engraving machine with ATOMSTACK APP, which helps Android and Apple cell phone methods. At the same time, It is provided with an unbiased operation terminal and emergency cease button to achieve fully offline engraving. You can also do your engraving work with several machines at identical times.

Specification

| General | ●Item Name: ATOMSTACK S20 PRO ●Brand: Atomstack ●Model: S20 Pro ●Type: Laser Engravers ●Status: Available |

| Features | ●Eye Protection Design ●Easy Installation ●Super High Power ●Upgrade Air Assist Kit ●Upgraded Laser ●Precise Scale Lines Axis ●Wide Compatibility ●Good laser sintering temperature ●12mm Solid wood Cutting in One-PASS ●8mm Acrylic Cutting in One-PASS ●It can even cut 0.5mm sheet metal ●Built-in Powerful air assist kit |

| Specifications | ●Machine Power: 130 W ●Laser Power: 20 W ●Laser Spot: 0.08*0.1 mm ●Focusing Type: fixed focus laser, no focusing ●Wavelength: 450-460 mm ●Routing Speed: 12000 mm/min ●Working Area: 400*400 mm ●Voltage Input: 100-240V 50-60HZ ●Connecting Interfaces: USB, Offline Use, APP ●Operating Systems: Windows, macOS, Linux ●Control Software: LaserGRBL and Lightburn ●File Type: SVG, DXF, JPG, JPEG, PNG, BMP, TIF, CR2, etc. ●Pressure: More than 120Kpa ●Free Flow: ≥25LPM ●Sintering Temperature: 1200 Celsius |

| Dimensions & Weight | ●Package Weight: 10.6kg ●Finished Engraver Size(L x W x H): 66X56.8X23.7cm ●Package Size(L x W x H): 57x52x18cm |

| Package Contents | ●2 x Support Beam ●1 x Y-axis Right Slide Rail ●1 x Y-axis Left Slide Rail ●1 x X-axis Rail ●1 x Laser Head ●1 x Air-assisted Machine ●1 x Control Box ●1 x Display Screen ●1 x Rubber Tube ●1 x Power Adapter ●1 x Power Cable ●1 x Safety Glasses ●3 x Foot Brackets ●1 x Synchronous Belt ●1 x Metal Mat Board ●1 x Fixed Focus Film ●1 x Mounting Screws ●3 x Wood Chips ●3 x Acrylic Sheet ●1 x HDMI Cable ●1 x USB Card and Card Reader ●1 x Toolkit ●1 x Wire Tie ●1 x Brush ●1 x USB Cable ●1 x Dust-free Cloth ●1 x User Manual |

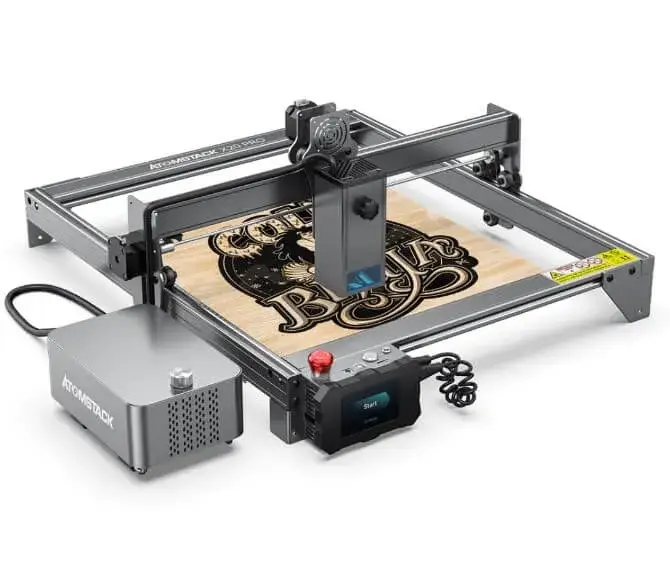

8. Atomstack X20 Pro

Atomstack X20 Pro 130W Quad-Laser Engraving and Cutting Machine Built-in Air Assist System

I couldn’t cover my pleasure until now as I noticed that the most highly effective diode laser of the 12 months comes out in a complete product.

Over the previous few years, there was an arms race concerning the general laser energy. Machines began at about 1.7 Watts, then 5.5 Watts; in the last 12 months, we started to see some 10-watt machines, like the Atomstack X7 Pro or xTool D1. And we’re beginning to see comparisons to the larger CO2 machines.

Atomstack X20 Pro Price

- Feature 1: 20W laser power, high power

- Feature 2: Strong cutting capability

- Feature 3: Can be engraved offline

- Feature 4: Equipped with an air assist pump

- Feature 5: Use your imagination to DIY

- Feature 6: 1 Year Warranty, Brand Guarantee

Features

Just this week, Atomstack, the well-known laser engraver producer, launched a tool known as X20 Pro on its official website. The machine claims to be geared up with a quad-core laser module, which consists of 4 6W laser beams coupled right into a single 20W tremendous laser beam.

The Quad-core laser represents the most superior know-how in the diode laser market right now, and the Atomstack X20 Pro deserves to be the world’s first 20W quad-core laser chopping and engraving machine.

We realized that the X20 Pro laser cutter has machine energy of 130W, and an important laser energy output is 20W. Atomstack Labs shows that it might probably lower 12mm of stable wooden in a single cross, 8mm of acrylic in a single cross, and even 0.5mm of thin steel paper.

Specification

| General | ●Item Name: ATOMSTACK X20 PRO ●Brand: Atomstack ●Model: X20 Pro ●Type: Laser Engravers ●Status: Available |

| Features | ●Eye Protection Design ●Easy Installation ●Super High Power ●Upgrade Air Assist Kit ●Upgraded Laser ●Precise Scale Lines Axis ●Wide Compatibility ●Good laser sintering temperature ●12mm Solid wood Cutting in One-PASS ●8mm Acrylic Cutting in One-PASS ●It can even cut 0.5mm sheet metal ●Built-in Powerful air assist kit |

| Specifications | ●Recommend Print Size: 400x400mm ●Carving Objects:Wood, bamboo, cardboard, plastic, and more ●Cutting Objects:Cardboard, non-woven fabric, wood board ●Machine Power: 130W ●Laser power: 90W ●Laser output power: 20-21W ●Wave Length: 445 ± 5nm ●Engraving accuracy: 0.01mm ●Focusing method: fixed focus laser, no need to focus ●Laser protective cover: Protect the user's eyes ●Operating software: LaserGRBL, LightBurn, support Win all ●Input Format: NC, BMP, JPG, PNG, DXF, etc. ●Data transmission method: USB connection. ●Input Voltage: AC100-240V, 50/60Hz ●Output Voltage: DC12V, 5A |

| Dimensions & Weight | ●Package Size: 57 x 52 x 18cm/22 x 20.4 x 7in ●Package Weight: 10.6kg/23.3lb |

| Package Contents | ●1 x Air Assist Accessory ●1 x Mounting Screw ●1 x Tool Kit ●4 x Foot Pad Foam ●1 x Film ●3 x Acrylic Sheet ●3 x Wood Chips ●10 x Wire Tie ●1 x Desiccant ●1 x Brush ●1 x Clean Cloth ●1 x Card Reader ●1 x TF Card ●1 x Power Adapter ●1 x Instruction ●1 x Data Line ●1 x Touch Screen Components ●1 x High Definition Multimedia Interface Cable ●1 x Laser Module ●1 x Cutting Pad ●1 x x Axis Assembly ●1 x y Axis Left Profile ●1 x y Axis Right Profile ●1 x Profile On The Base ●1 x Under The Base Profile ●3 x Foot Bracket |

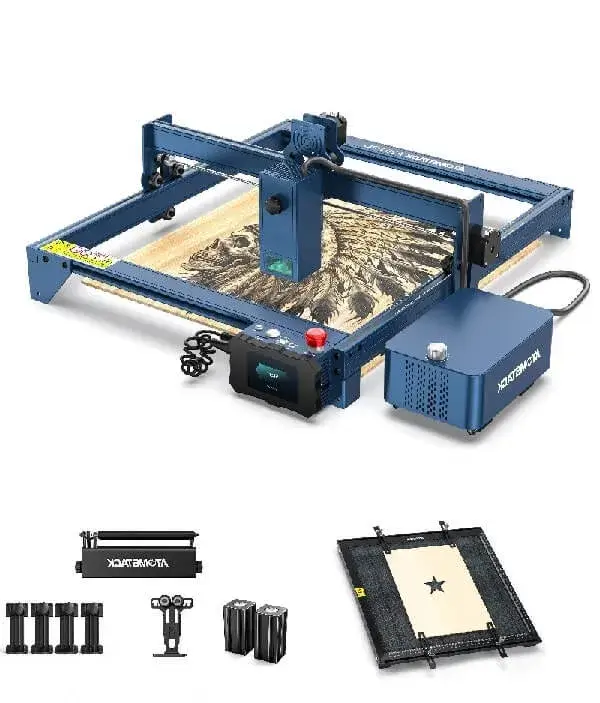

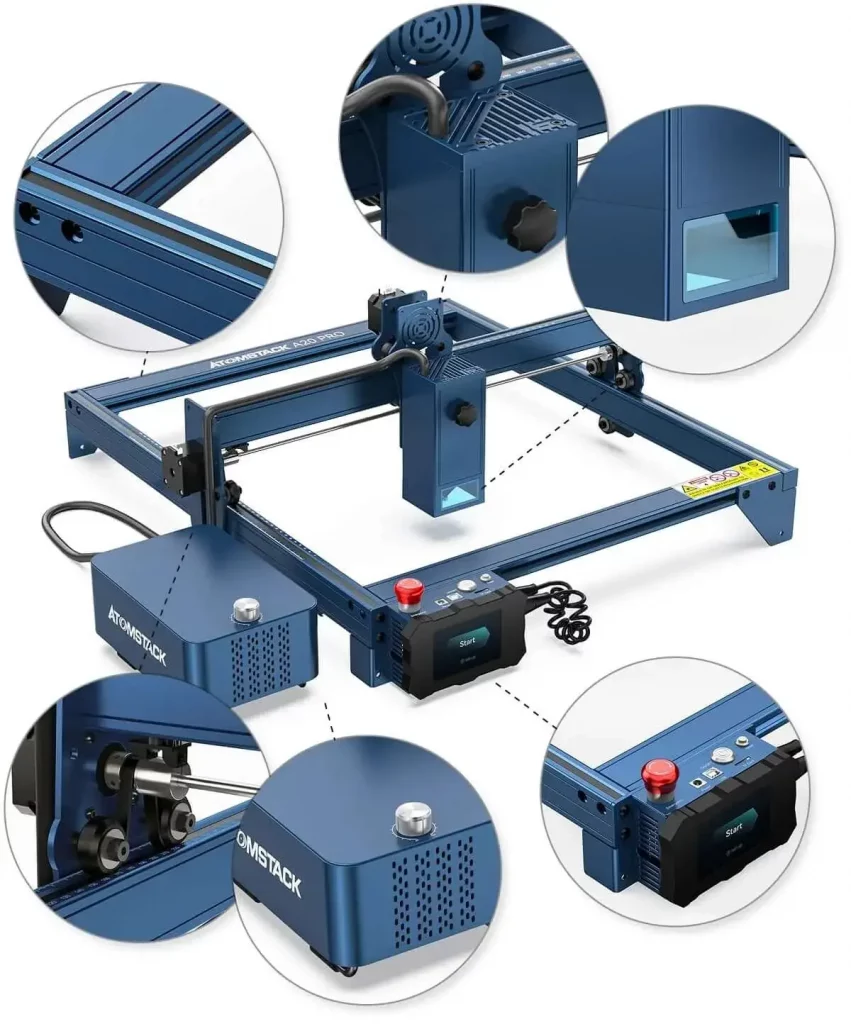

9. Atomstack A20 Pro

Laser engravers have increasingly set standards within the interest and hobbyist sectors. Atomstack A20 Pro is no surprise because the subject software of the engraver shouldn’t be precisely small. With gadgets like the ATOMSTACK A20 Pro Engraver, total photos could be transferred to wooden or different supplies.

You ought to most likely have seen our introduction of the Atomstack X20 Pro, the world’s first 20W laser engraver with essentially the most highly effective quad-core laser within the diode class of blue gentle out there. The A20 Pro is a equivalent to the X20 Pro; besides, the physique’s colour has been modified to blue.

Atomstack A20 Pro Price

- Feature 1: Super High 20W Optical Power

- Feature 2: Higher Accuracy Laser Engraving

- Feature 3: Upgraded Air Assist Kit and Software

- Feature 4: High Safety and Fast Installation

- Feature 5: Wide Compatibility

- Feature 6: Built-in Powerful air assist kit

Features

World’s first laser engraver with 20 W optical energy. The laser output energy will increase with the most recent technology of 4 6W laser coupling applied sciences and might reduce 12-15mm thick tungsten plate in addition to the 8mm thick black acrylic plate in only one cross and even the 0.05mm thick Cut stainless-steel sheet metal.

Its built-in 256bit coloration scale makes the ATOMSTACK A20 Pro engraving work higher, and the distinction is increased so that the engraving shouldn’t be solely black. Engraving doesn’t require focal size adjustment.

Specification

| General | ●Item Name: ATOMSTACK A20 PRO ●Brand: Atomstack ●Model: A20 Pro ●Type: Laser Engravers ●Status: Available |

| Features | ●Super high power first 20W laser engraver. ●The product comes standard with the F30 Pro upgraded air assit kit ●Newly upgraded Atomstack self-developed 32-bit motherboard ●Newly designed laser ●Atomstack’s self-developed mobile phone APP ●The new filter panoramic glass eye protection design ●Solid and easy installation structure design ●Upgraded high-performance fixed-focus laser ●Wide compatibility ●Precise scale lines axis ●Upgraded compression spot coupling technology ●Integral screw rod ●New laser with knob ●Support Offline Engraving ●The laser sintering temperature is up to 2400℃ ●Emergency stop button ●Stopper: Yes ●Reset switch: Yes ●Expandable engraving size |

| Specifications | ●Print Size: Recommend Print Size 400*400mm ●Carving Objects:Wood, bamboo, cardboard, plastic, leather, PCB board, aluminum oxide, non-reflective ●Electroplating layer and paint surface layer metal, 304 mirror stainless steel, glass, ceramics, cotton cloth, slate; ●Cutting Objects:Cardboard, non-woven fabric, wood board, acrylic, some thin plastic board, sponge; ●Machine power:130W ●Laser power: 90W ●Laser output power: 20-21W ●Wave Length: 445 ± 5nm ●Engraving accuracy: 0.01mm ●Focusing method: fixed focus laser, no need to focus ●Laser protective cover: Protect the user’s eyes and prevent pets from grabbing the laser spot. ●Operating software: LaserGRBL, LightBurn, support Win XP / Win 7 / Win 8 / XP / Win 10 system. ●Input Format: NC, BMP, JPG, PNG, DXF, etc. ●Data transmission method: USB connection. ●Input Voltage: AC100-240V, 50/60Hz ●Output Voltage: DC12V, 5A ●Certification: CE FCC RoHS FDA PSE |

| Dimensions & Weight | ●Package Size: 57 x 52 x 18cm/22 x 20.4 x 7in ●Package Weight: 10.6kg/23.3lb |

| Package Contents | ●1 x R3 Pro Rotary Roller ●1 × mounting screw ●1 × tool kit ●4 × Foot pad foam ●1 × Film ●3 × Acrylic sheet ●3 × wood chips ●1 × desiccant ●1 × brush ●1 × Clean cloth ●1 × card reader ●1 × TF card ●1 × power adapter ●1 × Instruction ●1 × laser module ●1 × cutting pad ●1 × X axis assembly ●1 × Y axis left profile ●1 × Y axis right profile ●1 × Profile on the base ●1 × Under the base profile ●3 × foot bracket ●10 × Wire tie |

10. Longer Ray5 20W

Longer Ray5 20W Laser Engraver: I used to be looking at the net and discovered that LONGER had launched their 20W laser engraver machine. By now, virtually all manufacturers have launched 20W lasers in this class.

The 20W diode laser module consists of 4 5.5W laser beams coupled right into a single tremendous laser beam, which may have a fantastic capability to improve chopping. The Longer Ray5 20W additionally makes use of this answer. Essentially the most direct enchancment is that it may reduce 15mm wooden, 8mm black acrylic, and even 0.05mm skinny steel paper in a single move.

Longer Ray5 20W Price

- Feature 1: 20W Laser Power

- Feature 2: Multi-Color Engraving

- Feature 3: 3.5″ Touch Screen for Offline

- Feature 4: Flame Detector

- Feature 5: 0.08*0.1mm Ultra-fine

- Feature 6: XY-axis Limit Switch

Features

Regarding spotting dimension, the 20W laser spot is bigger than the 10W due to its being coupled with several lasers. However, additionally, it is tremendously small. With compression expertise, it achieves 0.08*0.1mm, so whether or not it’s engraving or chopping, the Longer Ray5 20W can preserve excessive efficiency.

In case you choose to work offline, you should utilize the three. The 5-inch contact display screen comes with the machine by studying engraving information from the TF card or chopping information. It’s a shade display screen with respectable contact controls.

This time, the Longer Ray5 20W laser engraver has executed a fantastic job by way of security. Added X-axis and Y-axis course restrict switches, which may precisely find the place of the laser module. Similarly, suppose the laser module strikes within the detrimental course of the X-axis or Y-axis. In that case, Ray5 20W will set off an alarm and limit the motion.

Specification

| General | Item Name: LONGER RAY5 20W Brand: LONGER Model: RAY5 20W Type: Laser Engravers Status: Available |

| Features | Feature 1: 20W Laser Power Feature 2: Multi-Color Engraving Feature 3: 3.5″ Touch Screen for Offline Feature 4: Flame Detector Feature 5: 0.08*0.1mm Ultra-fine Feature 6: XY-axis Limit Switch |

| Specifications | Laser Technology: Diode Fiber Laser Working Area: 375*375 mm Laser Wavelength: 450nm – 460nm Focus Type: Fixed Focus – 30mm Focal Range Spot Size at Optimal Focus: 0.08 x 0.1mm Optical Output Power: 20W Z Axis-Height Range: Up to 65mm Engraving Speed: 10000mm/min Engraver Output: DC12V 5A Engraver Input: AC110 – 240V Software: LaserGRBL, compatible with LightBurn Connection: USB / TF Card / Wifi |

| Dimensions & Weight | Laser Engraver Size: 61 x 67 x 20cm Package Size: 621 x 347 x 127mm |

| Package Contents | 1 x LONGER RAY5 20W Laser Engraver 1 x User Manual |

5 Components to Think about When Shopping for a Laser Engraver

Shopping for an inexpensive laser engraver may be a troublesome process since tons of retailers are available on the market. Here are the five most necessary elements you could contemplate before spending cash.

1. Value

You need to purchase one thing you can afford, and your finances are crucial in figuring out the kind of laser engraving tools you should purchase. Even though the value may not instantly dictate the machine’s standard, it ought to be famous that most high-value engravers are usually costly.

This doesn’t imply that low-cost engraver and cutter instruments are unhealthy. However, your finances are a significant determinant within the decision-making course.

A tool that provides high quality and may engrave a variety of supplies will likely be robotically costly. In this case, try to be ready to spend extra money. However, you too can discover a cheaper variety that consumes much less energy and power. The largest worth determinants embrace:

- Laser energy

- Sort of engraving materials

- The engraving space

2. Software program Compatibility

There may be a variety of low-cost and inexpensive laser engravers for first-year students in 2022. However, quite a few software program merchandise is designed to be used with one of the best laser engravers.

Nevertheless, not all of them are suitable, resulting from entirely different specs and venture necessities. For example, it is best to contemplate Adobe Illustrator and Inkscape for those who want a software program product for illustration that may be suitable along with your machine.

Adobe Photoshop is an incredible possibility for those who want a photo-processing software program. In contrast, PDF records data are suitable with software program packages corresponding to Adobe Reader and Adobe Acrobat.

3. Materials Choices

The materials you propose to work with determine the kind of laser engraver you’ll ultimately purchase. Perceive that there are several sorts of supplies that may be engraved. They embrace plastic, wooden, glass, metallic, acrylic, and many others. Nevertheless, not all units can work on a lot of these supplies. Due to this fact, you must select suitable tools along with your wants.

4. Engraving Dimension

Engraving dimension issues because it impacts how the laser can etch a fabric and affect its floor end. Smaller sizes are necessary if you want much fewer materials, for example, 0.001 inches. Earlier than you put money into a laser engraver. It is essential to consider your area availability.

I’ve seen some people who find themselves interested in buying this gadget; however, advisors say they can’t function one due to the dimensions and weight – which might be a problem if the position isn’t potential or handy for accessibility causes.

5. Buyer Help

It’s the potential to run into issues when utilizing your tools. An available buyer help staff is necessary for serving you to deal with operational points. That’s why it is best to contemplate selecting the most excellent laser engraver from a good producer with several communication channels.

Laser Engraver & Cutter Information for Beginners 2023

In consideration of the number of customers who remains to be a newbie in laser engraving, so under is a piece of complete information that may go over the fundamentals of how laser engravers work, the different types accessible, and what it’s worthwhile to get began. So whether or not you’re simply beginning out or searching for extra data on utilizing your laser engraver, learn!

What’s a Laser Engraver Used For?

This engraving know-how works on different surfaces and supplies to create beautiful masterpieces with excessive worth. Consequently, a laser engraver has a variety of functions, together with:

- Signage

- Barcode creation

- Designing awards and trophies

- Creating digital parts and medical tools

- Crafting commemorative and ornamental annotations

Forms of Laser Engravers

There are three most important sorts of laser engravers, together with:

CO2 Laser Engraver: It utilizes carbon dioxide beams to penetrate the fabric. Nevertheless, it has a low efficiency degree; therefore, it’s ultimate for engraving and reducing non-metal supplies corresponding to paper, material, leather-based, and wood.

Diode Laser Engraver: it looks well-liked with hobbyists and makers. The diode on this laser usually is an optoelectronic gadget that converts electrical power to gentle, resulting in coherent gentle with excessive depth used to engrave objects.

Fiber Laser Engraver: It produces sturdy laser beams by pumping a particularly intense degree of sunshine through fiber optic cables. Observe that these cables are usually doped with ytterbium to launch high-capacity power within the type of photons.

How Does a Laser Engraver Work?

A laser engraver vaporizes supplies, producing fumes and leaving everlasting engraved marks. This tool uses a laser beam that acts as its chisel, exactly incising marks on materials by eradicating a considerable materials layer from its floor. The sting left behind could have a high-quality premium end on its floor.

Utilizing a laser engraver is effective because it hits all localized areas with an excessive power degree. This usually results in the technology of excessive warmth wanted for vaporization. The best laser engraving course is dependent upon the following:

The kind of materials being engraved

The vaporization course that’s ultimate for engravement typically depends upon the fabric’s flexibility to face up to temperature. Beneath is an instance of vaporization temperatures in levels celsius of various supplies:

- Zinc – 906

- Lead – 1750

- Aluminum – 2327

- Copper 2595

- Iron – 3000

What’s the Distinction Between a Laser Engraver and a Laser Cutter

These two items of apparatus are identical. Nevertheless, a laser cutter is a laser that has been optimized to lower shortly, employing supplies at sooner speeds than an engraved machine. Moreover, a laser cutter has the next lower commonplace, with a decrease in engraving commonplace.

In the meantime, a laser engraver has to decrease laser energy; therefore, it is lower, successfully utilizing the identical thickness degree as a laser cutter. Whereas it produces the next engraving commonplace, its lower commonplace is low.

What creates these essential variations is the laser lens of the machine. An engraving machine has a shorter focal size, leading to refined spot dimension and high-quality engraving. In the meantime, laser-reducing machines have longer focal lengths that tolerate object peak variations.

Tips on how to Use a Laser Engraver

There are two most essential steps concerned:

1. Put together the Materials

There are two sorts of supplies used with laser engravers:

Hardware: it’s worthwhile to put together the fabric you can lower with the cutter, which may be metallic glass, material, leather-based, forged acrylic, and wooden, amongst others.

The software program contains the application you’ll use to design the engraving. You want a pc program with vector graphics software, e.g., Adobe Illustrator or Inkscape, and so on.

When preparing the supplies, you need to use a warning signal since supplies corresponding to wood, acrylic, plastic, and paper are incredibly flammable. Aluminum can be highly reflective. The intention is to create peaceful working surroundings.

Think about the machine’s settings, together with energy and pace. This depends on the materials you’ll use and the impact you need to attain. For example, the glass may want excessive energy and medium pace, whereas acrylic reducing may have excessive energy and decreased speeds.

With some supplies, it’s essential to first experiment with reducing. Use the software program to attract your design or resize a pre-existing picture, after which, as soon as every part is prepared, go to File -> Print.

2. Materials Placement

Prep your laser cutter for materials placement by turning it on. After that, open the laser’s case, placing your materials where you propose to have your lower. Observe that the entire placement course can be straightforward if your laser cutter has in-built rulers.

You can modify the mattress for those who feel slightly dangerous with the position. Observe that there are various kinds of laser cutter beds, and so they embrace:

Thick-plate welded mattress: at the moment, one of the best laser cutter mattresses with an excellent lifetime and construction.

Solid-iron machine mattress: it might have a bubble inside, which can lead to mattress breakage

Sq. tube welded mattress: it’s reasonably well-liked, resulting from its cheaper value. It has excessive stress and a shorter lifetime, i.e., at most five years.

Materials for Laser Engraving

Laser instruments can etch or lower materials, its most critical and valuable process. So, the widespread supplies used for laser engraving embrace:

Glass: it’s one of many topmost laser engraving supplies. Laser jobs might be achieved on all glasses to provide esthetically pleasing results. It may be wine glasses, bottles, vases, and mugs.

Wooden: it’s a well-liked engraving material because it’s low-cost and available. Moreover, you need to use wood for laser engraving and reduction to achieve completely different outcomes. The everyday woods used for engraving include plywood, MDF, stable wooden/stable timber, pure wood, chipboard, HDF, and veneers.

Marble and granite: these supplies are principally used for engraving pictures, and it is because marble and granite are incredibly efficient in yielding an incredible distinction engraved. For a more wondrous esthetic enchantment, use dark-colored supplies.

Bricks and stones are perfect for engraving objects that will likely be uncovered in entirely different climate parts. This makes them ultimate for engraving items used on memorial websites and door patios.

Leather-based: These materials, similar to material, might be custom-made through engraving. Engraved leather-based is in excessive demand, and the most generally engraved supplies embrace pure leather-based, suede leather-based, artificial leather-based, napped leather-based, and Alcantara leather-based.

Metallic: all sorts of metals might be engraved. However, the commonest ones embrace chrome steel, iron, brass, aluminum, and silver.

Acrylic: It’s a sturdy, dependable, and lightweight various to glass. There are two sorts of acrylic sheets, i.e., extruded and forged. Consequently, they each reply otherwise to the engraving course. Solid acrylic sheets typically produce a frosty white look in distinction to the unique materials. However, extruded acrylic usually stays clear because it only produces a little distinction.

What Machine Setting does a Laser Engraver Embody?

Laser settings decide the output of the cutter. For example, sooner speeds typically point out that the machine could have lowered publicity time along with your materials and vice-versa. The four most important sorts of machine settings embrace:

1. Energy

The facility setting controls the quantity of power degree within the laser tools. It’s worth noting that the power ranges within the laser will increase when the ability increases. Typically, the power required to penetrate a fabric usually varies depending on the kind and thickness.

Deeper cuts and perpendicular partitions want extra power than skinny conical shapes since extra power will likely be wanted to take away extra materials.

Observe: extraordinarily excessive power ranges can result in charred edges and smoke. In total, much fewer energy results in straighter edges and shallower cuts. In the meantime, extra energy results in vast edges and deeper cuts.

2. Velocity

Velocity impacts how briskly or slows the laser carriage will transfer around. There’s a direct relationship between pace and energy(power). To get this, it’s worthwhile to perceive that the longer it takes power to be uncovered in space, the extra power that space will obtain. Due to this, the pace can be utilized to regulate the length of power targeted.

A decreased pace results in a slower reduction, however, with deeper cuts, whereas the next pace results in a sooner reduction, however, with shallower cuts because the quantity of power centered to some extent in such a situation is lowered. Perceive that your design might find you with undesirable edges if the pace could be more active or quick.

3. Frequency

The frequency setting of a laser engraver is typically given in Hertz (HZ). This decisive parameter signifies the variety of laser pulses generated in a second. For example, a CO2 laser can have a frequency variety of 1,000 Hz – 60,000 Hz.

In some cases, the frequency may also be known as Pulses Per Inch (PPI). It offers you the last word management on the number of instances the pulses might be highlighted over a given object distance in the engraving or reducing course. Observe that the higher the frequency, the more output pulses will likely be generated. This can ultimately lead to an overlap of the pulses, resulting in a smoother lower.

Nevertheless, the following frequency worth means extra warmth will likely be generated in the course of the reducing course, which might result in the charring or melting of certain supplies. In the meantime, a decreased frequency implies that fewer pulses will likely be generated in a spaced-out approach, which usually results in making a perforated line.

4. Focus

The main target is necessary to offer one of the best-reducing impacts based primarily on completely different material thicknesses. A laser beam wants to focus on a selected space by “focusing” gently on it to facilitate engraving or reducing.

To regulate a laser engraver’s focus, modifying down the Z-axis is worthwhile, relying on the fabric thickness you’re utilizing. Merely measure the thickness of the fabric you need to engrave, then go forward and modify the engraver’s backup based on the attained degree of thickness.

You can focus a laser cutter utilizing a single Len or multi-lens optic, which usually depends upon the free aperture’s diameter and the focal size.

Tips on how to Construct a Laser Engraver

If you have a spare Arduino and a DVD drive, you can create a number of DIY laser engravers. To make sure that you discover an approach that fits your wants right here is likely one of the most straightforward DIY choices to think about: DIY Laser Engraver with RGB.

It’s the most inexpensive and extraordinary laser DIY initiative you can do. With this method, you want an Arduino, RGB controller, laser security glasses, two outdated DVD drives, MDF, screws, and scorching glue. Please begin by preparing the actual construction, e.g., reducing the MDF to raise the cables and LEDs. For a cleaner look, you can encase the laser tools.

Step 1: lay the tools’ fundamental construction on the drafting board

Step 2: draw the life-scale design of the help facet items

Step 3: get the rails out of the DVD drives

Step 4: Create the X-axis help plate from the 2 MDF layers. The help plates must adapt to the DVD driver rails’ form. It would be best to use the essential wooden glue to hitch the two items. However, earlier than you do that, guarantee that you’ve successfully sorted the place the laser’s cable will go to the motor.

Step 5: Create a room for the RGB’s LEDs. Observe that the LEDs must be hidden in between the MDF items. If potential, use a knife to dig accessible groves for the cables and LEDs to undergo. This may also create the right channel on your X-axis motor cables.

Step 6: Get skinny wire. Because the grooves gained’t be immensely vast, you want a skinny wire to attach the LED. It would help if you used ethernet or USB cables to get the skinny wire.

Step 7: Paint your Laser cutter and wrap every part up! If you have time, you can reinforce the construction of your gadget with extra sturdy materials.

For those who did some analysis, there are nonetheless different DIY methods you could contemplate implementing, together with:

- DVD Drive to CNC Laser Engraver

- DIY Arduino Mini Laser Engraver

- Pocket Laser Engraver

- DIY Wi-fi Laser Engraver

Anyway, Beneath is a video to point out your: Tips on how to make CNC LASER engraver DIY from the DVD drive.

What Software program Can Be Used for Laser Engraver and Cutter

With the appropriate software program, laser engravers and cutters might be excellent. Chopping and slicing through supplies with a concentrated gentle beam may seem easy, but getting the exact product design requires using a high-quality software program.

1. Lightburn

It’s a management and editor software program package deal. Lightburn is used to import a variety of bitmap and vector graphic picture codecs. This software program permits you to create new artwork, edit, and prepare your vector graphic. A laser engraver is environmentally friendly since you can ship your File onto the machine.

Options

- Works with various widespread picture codecs and vector graphics, together with AI. DXF, SVG, GIF, PNG, PLT.

- A local software that’s written for Linux, Home windows, and Mac OS

- You can create, prepare, and edit new vector shapes within the editor.

- Several highly effective options corresponding to welding, node enhancing, offsetting, and Boolean operations

- It has several passes, pace, energy, dithering mode, lower order, brightness, and distinction.

2. Laser GRBL

It is a free laser engraving software program designed for DIY laser engravers. Rated as the most sought-after Home windows GCode streamer, you need to use this software program to load or stream your GCode path to engrave photos, pictures, and logos. Its distinctive options are enhanced as a result of it being mainly developed for a hobbyist laser engraver and cutter.

Options

- Powered by user-defined buttons

- Excellent for picture engraving with vectorization, dithering, and grayscale conversion.

- GRBL configuration for import and export

- Affords real-time projection and job preview

- It affords utterly different color scheme optimization to be used with numerous security glasses.

- It has a homing button, resume button, feed maintenance butting, and GRBL reset button.

3. Inkscape

It’s a free and open-source software program popularly thought of as the simplest various of Adobe Illustrator. The truth aids its reputation of continuously evolving and enhancing consumer expertise when coping with laser engravers.

Options

- Its native format is scalable vector graphics (SVG)

- It gives royalty-free graphics formatting- markup language, i.e., you must use instructions to create your distinctive designs.

- Runs on all OS platforms with equal ease, together with Home windows, Linux, and Mac OS

- Has clones, pencil instruments, form instruments, and textual content instruments for object creation

- Facilitates object manipulation utilizing grouping objects, transformations, elevating and decreasing operations, layers, and alignment and distribution of instructions.

- Fill and stroke with sample fills, path markers, color selectors, and dashed strokes, amongst others.

- Affords textual content help with textual content in a form, multi-line textual content, textual content on a path, and letterspacing, amongst others.

4. Adobe Illustrator

It’s currently rated because of the industry-leading vector graphics software program. With Adobe Illustrator, you can scale your paintings for cellular or billboard dimension screens. The premium design begins with adobe illustrator. This software program can create net graphics, logos, packing, and icons, amongst different issues.

Options

- Sharp at any scale: this lets you deliver your concepts to life

- Sensible and quick: the software program is powered by Adobe Sensei AI, allowing you to create design

- content material shortly. Observe that you can recolor your work with a click or create customized results!

- Enhanced 3D results: give your vector drawings these distinctive 3D seems to be by enjoying lighting choices,

- extruding, and rotating the design in a 3D panel

- Computerized font activation: this function robotically searches and prompts all of the accessible Adobe fonts

How Do I Create Designs for a Laser Cutter?

How will you successfully create high-quality designs on your laser cutter? No matter your skilled standing, an entrepreneur or an engineer, you can manufacture merchandise with excellent designs at low prices with excessive precision and pace utilizing a laser cutter.

However, a key factor to notice is that laser machines comply with particular design pointers to satisfy high-quality necessities and design precision.

Use a suitable software program to create the vector records data.

Firstly in the design operations, all laser cutters want vector records data. You make such records data utilizing Inkscape or adobe illustrator. The widespread vector records data might be within the codecs corresponding to them. Step, .ai, .eps, and .dxf amongst def. Others.

Use a completed dimension to scale the design.

Earlier than you can lastly use the design with the laser cutter. It is best first to make sure that the completed dimension is scaled. For example, if the product is supposed to measure 10 inches squared, its design must have identical measurements. If that’s not the case, the product will have inappropriate proportions.

Submit the ultimate design to the cutter

Particularly submit the ultimate design ONLY to lower the laser. Any extra data corresponding to gridlines, feedback, marking, and further notes should be eliminated as they are separate from the ultimate product.

Bridge the design

New creators typically need to pay more attention to attaching the design. Bridging is necessary because it helps preserve your shapes within the significant materials. Total, including bridges, is necessary for permitting the laser to lower the design and preserve it collectively without lacking the necessary elements.

Perceive that laser machines can’t course of texts, and if there are any, it is best to contemplate changing them into outlines or shapes. It is an easy course, and you can do it by hovering the cursor over the textual content after selecting the enhancing bar with an energetic textual content field.

Delete Open Shapes and Intersecting Traces

Laser cutters can only work with finished shapes or these which can be open. So, all of your designs have to be self-contained and complete. If that’s not the case, the top product will likely be completely different from what you envisioned in your design.

Moreover that, all intersection traces ought to be eliminated since this will likely be handled as an overlapped design. Leaving a design with intersecting line implies that the laser cutter will lower any traces within the design, ensuing in the lack of necessary traces and damaging the entire product design.

Use Giant Cutouts

It’s useful for your cutouts to be a minimum of larger than 1X the thickness of the fabric used. Smaller cutouts are usually inefficient within the cutout course because the laser cutter might fail too successfully. Moreover that, this tool treats small designs as delicate.

Think about the Design Materials

So, which materials are suitable for your design? It is a crucial facet in creating laser designs on your cutter because of the efficiency of the fabric issues. Typically, laser cuttings are made utilizing chrome steel, copper, cold/hot-rolled carbon metal, and aluminum brass.

Additional laser cutter design creation data might be discovered by watching YouTube movies corresponding to:

Design Suggestions for Excessive-High quality Laser Cuttings

To create design cuttings like a professional, listed here are a couple of suggestions that can assist you:

The kind of design file format you want: To organize a laser-reducing design, create a vector file, unlike a PNG or JPG picture manufactured from pixels that may lose their authentic high quality when resized. Nevertheless, a vector file gained’t loses its properties.

Sort of software program: Two sorts of software program work with laser reducing, i.e., 2D or 3D. The 2D software program is suitable for graphic designers who create banners and logos. However, this might solely be the ultimate for flat objects. The 3D software program is suitable for engineering and mechanical initiatives.

Forms of 2D Software program

- AutoCAD

- CorelDRAW

- Adobe Illustrator

- Inkscape

Forms of 3D Software program

- FreeCAD

- Solidworks

- Autodesk Fusion

- Autodesk Inventor

Think about the kind of materials and their thickness: several supplies can be utilized to create laser designs. Acrylic is understood for its waterproof traits and excellent flexibility, and cardboard is inexpensive for venture presentation. Moreover, the thickness of the fabric performs a necessary function within the design. Usually, the thickness ranges between 1 to 10 mm.

- Remove line overlapping: contemplate the minimal size between two reducing traces because if the traces are too shut, the laser beam will soften the fabric.

- Join the necessities: assemble the nodes, edit the perimeters of the slots, and so on. However, at the,e finish of your design creation, ensure your design.

Rotary Attachments

A rotary attachment is a gadget plugged into the laser cutter to facilitate engraving on rounded objects. Typically, a laser cutter is designed to function straight down. Consequently, it will successfully engrave on the underside and sides of an object. However, because the laser fires, the rotary attachment can revolve across the object, allowing you to engrave your design entirely.

However, when is the perfect time to use a rotary attachment? For this plugin to work correctly, the article must be positioned symmetrically across the tall axis from high to backside. This fits the profile of wine glasses, water bottles, and rolling pins.

If the article isn’t completely spherical, the engraving might be skewed because of the object falling off the rotary attachment. It’s because the middle of mass will shift as the article rotates. For effectivity, the article’s line of symmetry must be constant. Moreover that, rotary attachment issues might be brought on by object unevenness.

A certified workers member should solely use this sort of plugin for effectiveness. Moreover that:

- It’s advisable to run the preliminary take a look at with zero energy and excessive speeds to find out if the article will rotate correctly.

- If you’re utilizing a glass object, train warning.

- Avoid being tempted to use soap on the article to boost the rotation since this may simply outcome result object shortly slipping off your rotary attachment plugin.

- The item should be sealed earlier than positioned within the engraver, i.e., remove any water and filth.

- Successfully arrange the working area, together with the peak, which ought to be the complete circumference of the engraved object.

Laser Engraving Security Precaution

Using a laser engraver might be harmful and poisonous to your well-being. To guard yourself against the fumes and beams right here’s what it’s worthwhile to do:

Laser Beam Safety

Lasers may cause vital harm to your eyes. For security functions, it’s essential to contemplate carrying laser security glasses. When selecting such a protecting instrument, it is best to contemplate glasses that instantly complement the laser engraver you’re utilizing.

This should be straightforward since laser data might be discovered within the instruction guide. This contains data because the optimum density and wavelength vary, normally nanometers. Alternatively, you can also seek the advice of a laser security officer. Be sure to put on your laser glasses in the course of the engraving course and solely take them off after getting stopped utilizing the tools.

Fumes

Laser cutters generate fumes, particulates, metallic fumes, and vapors from substrates which may be highly poisonous. It’s necessary to put on Personnel Protecting Tools (PPE) when working a laser cutter. Moreover that, workshops with these instruments should have well-fitted filtration programs, which is necessary for decreasing the probability of well-being hazards brought on by poisonous fumes.

To maintain up with Occupational Security and Well being Administration (OSHA), laser-reducing workshops ought to have fume extractors that adjust to the stipulated protocols. Fume extractors are perfect for such workplaces since they assist in extracting harmful fumes from the air, defending you in opposition to publicity of heavy metals and poisonous particles.

Potential unwanted side effects of laser fumes publicity embrace:

- Metallic fume fever: that is usually brought on by zinc fumes launched when reducing certain metal alloys.

- Widespread signs of zinc fumes embrace aches, coughing matches, flu, and fever.

- Irritation: chemical publicity can irritate the eyes, pores and skin, mouth, and noise.

- Toxic chemical buildup: over time, the poisonous fumes accumulate within the physique resulting in undesirable chemical reactions. This may ultimately lead to lead poisoning and kidney issues.

- Publicity to carcinogenic compounds is prevalent, mainly when hexavalent chromium may exist. It’s a harmful particle that may end up in most cancers.

- Moreover, several analysis research points out that this nasty particle can instantly lead to several unwanted side effects, corresponding to pores and skin sores and irritation of the nostril, mouth, and eyes.

Air Airflow

Laser machines, particularly those with CO2, typically produce harmful fumes, which is why these units must be vented. Due to this fact, you must contemplate working in a well-ventilated area.

Whereas fashionable laser engraving programs are designed with exhaust air flow programs that preserve the inside of the laser cutter and the air across the laser protected, make sure that you open doorways and home windows without spending a dime on airflow.

Different extra security measures embrace:

- Using correct tools storage: your protecting glasses should be saved all the time in a person’s case and a protected unit. This can assist in attenuating the probability of publicity to contaminants and removing scratches.

- Observe the stipulated laser engraving protocols: make sure your facility complies with legal guidelines and rules concerning the use of laser cutters in workshops.

- Use warning indicators: if there are several human actions in your workshop, use warning indicators. These should be easy-to-read indicators appropriately positioned and designated areas corresponding to entries.

- At all times, clear up the litter: take away the flammable supplies and particles amassed after utilizing a laser cutter. Moreover, please don’t remove the fabric from its reducing mattress instantly; wait till it has cooled down.

Beneath are additional particulars about security guidelines for laser engraving

How skinny Can a Laser Cutter Minimize?

A laser cutter is designed for chopping into supplies of varied thicknesses. Moreover, you can function in various reducing circumstances to successfully attain supplies of various thinness or thickness—one of many fields where this tool is broadly used within the medical area in refining medical instruments.

Via laser pulse mode, it’s the potential to achieve finer options with excessive tolerance and completely different sizes. Fantastic lase can successfully lower a skinny width of 20-30 microns. Typically, it’s the potential to achieve particularly excessive dimensional management by routinely adjusting the laser to +/- 0.001 inch. In medical reduction, it can focus down the laser to a 0.001-inch diameter. This effectiveness is enhanced because laser reduction doesn’t rely upon touching any materials half.

Moreover, no mechanical drive must be exerted during the reducing course on the fabric. There isn’t any drag or push impact that may have a wrong impression on the thinness of the fabric. However, perceive that when the reducing accuracy is much less advantageous, the reducing speeds are rapids and vice-versa.

How Lengthy Does a Laser Engraver Final

Most laser engravers available in the market have a lifetime of around 30,000 hours. However, you can discover good tools with over 35,000 hours, which can interpret to be greater than 15 years if used correctly.

Can You Make Cash with a Laser Engraver?

Sure. It would be best if you used such tools to make personalized product designs, lettering, and logos. In a world where everyone is attempting to be completely different, this is good for an enterprise that wishes to create distinctive objects.

Customization helps extend a product’s worth, so you need to use it to generate good-looking revenue. Laser engravers earn a reasonably good wage from their vast software in several industries, and you’re assured earnings.

Laser Engraver vs. 3D Printer

For creatives, getting machines that finally meet your wants is necessary. So, get a laser engraver or a 3D printer. Each instrument encourages creativity and permits customers to study new abilities. Selecting one is a relatively posh course.

3D printers are used in additive processes since they supply an environment-friendly approach to including or utilizing supplies to create unique merchandise. With a 3D printer, you’ll create one thing new from scratch, e.g., jewelry, prosthetic bones, and even elements of buildings!

In the meantime, the design of laser engravers relies on subtracting. To realize new shapes and designs, some supplies must be eliminated. So, what are some great benefits of a laser engraver and a 3D printer?

A laser engraver is suitable for angular initiatives and people who want flat layers. In the meantime, the good thing about a 3D printer is that it may be used to create irregular and healthful 3D objects from scratch.

A laser cutter and 3D Printer could also be used throughout different phases of the product creation course of., for example. It would help if you used a 3D printer to make inexpensive product prototypes earlier than transferring to complete product manufacturing. In the meantime, you need to use the laser cutter to refine the product’s look during the last phases. Observe that some individuals use the 3D Printer during the last phases of product growth.

When creating prototypes and objects, a laser cutter is quicker. As a substitute for a printer to derive small shapes out of wood, it would take your cutter a couple of cuts to achieve the job. It takes time to make use of a 3D prototype because you first must generate the form out of its filament, which may also result in different operational prices of the fabric.

Filaments have for users to create a 3D-printed object. Consequently, they might need to be more efficient in creating the output’s perfect performance or esthetic enchantment. However, the filament can nonetheless be handled to alter the article’s look. With a laser cutter, you’ve assured a variety of fabric compatibility, and consequently, you can experiment.

Even though laser cutters are environmentally friendly, they’re usually costlier than 3D printers. Suppose you are searching for a less expensive one. In that case, it is best to contemplate a 3D printer, and spending extra to get a laser cutter ensures reliability.

Laser Engraver vs. CNS Router

A CNC router is a computer-controlled machine for reducing, drilling, and milling supplies. Typically, it’s much like commonplace milling machines. However, you automate it by utilizing a pc numerical to regulate the instrument paths.

Laser engravers and CNCs function equally. However, the distinction lies in how the reducing course typically happens. A laser engraver depends on warmth to generate the product’s desired form successfully. It is a high-energy gentle beam centered on a selected part of the fabric. However, the standard CNC typically carves a design out of a product.

In the case of fashionable wooden reducing, what’s the benefit of a laser cutter over a CNC router and vice-versa?

A CNC router might be adjusted alongside the Z-axis, up and down, to chop exact depths, which can be straightforward to regulate. This means that the peak of the CNC router’s cutter might be adjusted on some wooden surfaces to change into simpler to regulate.

CNC routers are perfect for designing merchandise that wants rounded corners. If the operator has the appropriate technical know-how, the instrument can spotlight an excellent degree of expertise. The downside is utilizing a CBC to create sharp angles because it has a radius limitation. Moreover, that, reducing labor is extra intensive.

The carved nature of CNC routers helps remove the probability of discoloration on the surfaces or edges of the wooden floor. Moreover, you may have higher management over the accurate dimension of the article’s depth, and you’ll conveniently work with thicker wooden items.

Lasers act like automated routers. However, as a substitute for carving the wood away, these units use a high-energy beam of sunshine to burn through the wooden materials. Consequently, they supply excessive precision cuts, and this generally seems like working with a magic marker with a finely-tipped pen.

Since engravers burn to utilize wood, they produce clear, sealed, and crispy edges. Nevertheless, you should be ready to take care of the downsides of burning discolorations that may leave undesirable wooden marks. Nevertheless, burning is nice because it helps seal the perimeters, thereby minimizing the probabilities of wooden extraction and growth.

You can create only two sorts of depths with a laser on the wooden subject of depth. You could have an opportunity to make use of the engrave or lower possibility, and that is an enormous limitation since you possibly can’t use a laser cutter to create numerous multi-depth cuts which can be detailed. For versatility, you can solely stack your layers on high of one another after the laser has lowered/burned to utilize them.

All these variations assist in setting these two machines aside and make it easier to discover the perfect areas where they thrive.

Final Thought

In conclusion, a laser engraver is a beautiful instrument for creating intricate and correct designs. It’s ultimate for people searching for an exact and environment-friendly engraving approach in numerous supplies.

The perfect laser engraver in 2023 will possibly have superior options corresponding to intensive laser beams, higher accuracy, speedier etching instances, and extra utilization choices than ever earlier. It’ll be fascinating to see over the subsequent couple of years which producer rises to the highest and what revolutionary fashion enhancements they implement into their new merchandise.

Whereas this information has outlined the standout traits of every of the high laser engravers popping out in 2023, please consider what it’s worthwhile to get out of an engraver and use this data to assist in making your last determination.